|

Home

::

|

My Antique Lister CS Diesel Engine Project

By Ben Azari

"Army Radio Sales Co."

This got me thinking, there must be a better way to generate electricity at the lowest possible costs, both initial start-up costs and in running costs. Sun power was not even considered at this point as it is a complete waste of time in England "It rains or is cloudy almost all the time". We are lucky to have 2 weeks of continuous sun light without rain in the summer.

The next best option is to have a mechanical motor connected to a AC generator, running on some sort of fuel, be it Petrol "too expensive", Gas "too Expensive" or Diesel "better but still too expensive".

But if one was to choose a diesel engine then as it is diesel it can run on Vegetable Oil, and if vegetable oil then it can run on used vegetable oil from restaurants for free! This is a much better option than wind generation especially on my pocket.

Environmentally not 100% green as wind or sun generators but just as good as. Burning used vegetable oil makes sense, plants while growing absorb gases from the atmosphere these gases we release back in the atmosphere when we burn the oil in an engine, so technically we are not adding anything back in the atmosphere that was not there in the first place.

I remembered many years ago I saw a very old slow running engine with two big flywheels on a farm which was used as a water pump and ran on diesel, one of these engines would be perfect for generating electricity. A quick search on Google about "Stationary Engines" produced a lot of results and I soon found the engine that I had seen so many years ago.

It turned out to be a Lister type CS diesel Engine, but were do I find one from? so I looked on eBay and there it was!

Lister type CS 600 RPM 3 HP engine. 3HP is not a lot of output power, but should be able to drive a 3 or 3.5 KVA AC generator with no problem which will provide me with most of the power I need to run my home, also as it is water cooled and I should be able to reclaim some of the heat from the Engine cooling system and the engine exhaust to run some form of heating system for the house. I thought as it is only an experiment the 3HP engine would be OK to begin with and if I find that I need more power then I would get a bigger 6HP engine.

| eBay Auction Listing For The Engine | |

|

I told my wife about my plans and showed her the eBay auction for the Lister CS engine that I was planning to bid on. She was totally unimpressed about the whole idea!

To win her over I promised her that we will save money on fuel bills "not sure at this stage" and that I will keep it in the shed at the bottom of the garden and not in the garage next to the house "The engine should really be next to the house for short hot water pipe runs". She was also worried about the noise it will make while running and I promised that it will be so quiet that we will be able to sleep next to it and no one will be able to hear it running. "I really have no idea at this point how noisy it is going to be".

So far so good and she is coming around to the idea, while waiting a few days for the eBay auction to end, I do more research on the Lister CS engines instead of answering customers emails about radios.

As it turns out I am not the first person who has thought of using a Lister CS engine to generate power with used vegetable oil. I get the manuals on the engine and read about other peoples experiences. All looks very interesting and doable. Did you know you can buy these engines new from India. They are locally made copies of the original Lister engines. Indian prices are not bad at all for a new engine, but I rather have a original British engine and not a copy. As it turns out the Lister on eBay I was looking at was made some time in the 1940-41 "War Time Dated" so even more reason to get this particular engine. Lister CS engines were originally designed in the 1920's and made from 1930's to 1980's in England.

| Engine Specifications | |

| Manufacturer: Lister "England" | Bore: 3-3/4" |

| Type: 3-1 "4 Stroke Stationary Engine" | Stroke: 5-1/2" |

| Spec: 208/12 | Power Output: 3HP @600RPM |

| RPM: 600 | Number of Cylinders: One |

| Serial Number: CS 35881 | Fuel: Diesel Oil |

| Approximate Year of Manufacture: 1940-1941 | Cooling: Water Cooled |

I won the eBay auction, the good wife was very disappointment but I was happy, I got it for a good price and I was looking forward to restoring something mechanical for a change instead of the usual radios. The engine was in Shropshire and I arranged collection for the following weekend. I borrowed my friends small van, "the one who asked about wind generation" and went up in the morning to collect the engine. Found the farm with some difficulty as it was in a mobile phone dead spot. The seller was very helpful in loading the engine in to the van, but we had to lye down the engine as it was too tall to fit in the van standing up. On the way back I had to stop and tie the engine down to the floor of the van as the flywheels were acting like wheels and the heavy engine was moving every time I was accelerating or braking. Not a good idea to have a loose engine in the van, but it proved that the engine was not seized.

The next morning we made a ramp and wheeled the engine off the van to the floor. This is some heavy engine, but it was very easy to wheel it off on its own flywheels, good thing I tied the engine down on the way back or it could have been disaster waiting to happen.

Lister CS Diesel Before Cleaning |

|

Lister CS Diesel Before Cleaning |

|

Lister CS Diesel Before Cleaning |

Lister CS Diesel Before Cleaning |

|

Lister CS Diesel Before Cleaning |

|

Lister CS Diesel Before Cleaning |

Water Jacket Deposits |

|

On closer inspection of the engine I found two hairline cracks on the water

jacket around the cylinder. I was a bit disappointment at this stage as I wanted

to get the engine running as soon as possible, now I have to send away the

cylinder block so it can be welded professionally. The crack in the water jacket

was probably due to frost damage. While washing the engine I some how managed to get some water in to the cylinder and I could hear it gargling inside the cylinder when the flywheels were turned, so off comes the head followed by the cylinder block. There was so much rubbish inside the water jacket that cleaning it the normal way would have taken a long time. The Jet Washer came in to the rescue and it cleaned out most of the dirt from inside the water jacket around the cylinder and the head. The very hard deposits was chipped away using a small hammer and a flat screwdriver as a chisel on the work bench. The cylinder and piston looked to be in good shape, but the oil scraper ring on the piston is missing!, there are no scratches inside the cylinder to suggest that it broke off and I was careful when I took the cylinder off. There was no way it could have come off, so it probably was not fitted from new "very unlikely" or it was not fitted some time in the past when the engine was last serviced, maybe it has fallen in the sump, who knows. Now I have 2 problems on my hand, the cracked water jacket and the missing piston ring. |

||

Exhaust Port Deposits |

There was too much hard deposit accumulated in the cylinder head over the years which could not be cleaned with the Jet Washer so I had to chip away at it through the water passage holes. A lot of rubbish came out this way. The valves had to be removed next. I looked in the workshop to find my valve press, but could not find it. Then I just tried pressing hard the top of the valve with my fingers and realised that the valve springs were not that strong and I managed to remove the valves that way! In my experience working on modern engines removing the valves with-out a valve press is impossible, so maybe my valve springs are weak. I have to look into this later. The exhaust port was almost completely blocked with carbon. No wonder they stopped using the engine. The carbon was chipped away until I had a clean exhaust port.

|

Cylinder Head |

|

Cylinder Head |

|

Piston and Rings |

Injector Before Cleaning |

|

Compression Changeover Valve |

|

Exhaust Valve Lifter & Valve Tappets |

Fuel Injector Pump |

|

|

Governor Spring and Linkage |

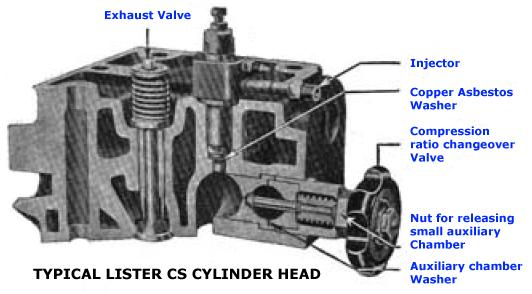

Lister Cylinder Head, The Engines Face! |

|

Background on Lister Engines In 1929 - 1930 Lister introduced the first of their Cold Start "CS" single cylinder diesel engines. Until then due to lower running compression all diesel design engines had to have their combustion chambers preheated by the user with some type of torch before starting the engine from cold. Lister came up with a clever but simple

solution of having a small chamber built in to the cylinder head. The access to

this chamber was with a hand operated valve, mounted on the side of the head. To

increase compression for cold starting, the valve was closed restricting access

to the chamber. When the engine was running the valve would be opened to allow

the extra space in the chamber to lower the compression to normal operating

parameters. |

|

Lister built variations of this diesel engine and the "Cold Start" or CS models where available as singles, twins and 4 cylinder models. These new CS engines were very reliable requiring minimum maintenance, simple to service using a few tools and became very successful. Thousands were manufactured for home use and exported throughout the British Commonwealth performing a variety of tasks.

During the 1950's the 3-1, 5-1, and 10-2 engines were slightly up-rated in speed from 600 to 650 RPM producing slightly more power. The 3-1, 3-2 engines were discontinued in 1952. The 6-1 continued to be manufactured until 1974 and the 12-2 until 1975. The 8-1 was manufactured until 1987 when Lister stopped production of these engines.

A lot of these engines were exported to British India until the British rule ended in 1947. The new Indian government banned the importation of British products including Lister engines and spare parts. People started to bring in their own parts to keep the engines running. Some enterprising individuals started to assemble their own engines from parts brought over from England at high cost. They soon realised that they can reproduce casting parts locally and started to manufacture spare parts at low cost. The demand was very good for locally produced spare parts and soon they were able to manufacture complete engines to the original Lister designs. Today there are several Indian companies that are still producing copies of these engines known as "Listeroid Engines".

Brush 5KVA Alternator |

|

It was some time near the end

of end of Jan. 2007 when "Big Mike" got in touch and offered a 5KVA Brush

Alternator to me. I was searching for a suitable alternator for my Lister CS

Diesel Engine project for almost a year and I accepted the offer in exchange

for a very nice HF radio set! Here are a few pictures of the Brush Alternator until I find manual before I attempt to restore it. Please Help With The Manual! |

The Brush Alternator

It was some time near the end of end of Jan. 2007 when "Big Mike" got in touch and offered a 5KVA Brush Alternator to me. I was searching for a suitable alternator for my Lister CS Diesel Engine project for almost a year and I accepted the offer in exchange for a very nice HF radio set!

Here are a few pictures of the alternator until I find manual before I attempt to restore it.

Any details such as a manual to restore and use this Brush Alternator would be greatly appreciated.

| Brush Alternator Specifications | |

| Manufacturer: Brush Electrical Engineering Co. Ltd. | Rating: CM |

| AC Volts: 240 | P.F.: 1 |

| AC Amps: 20.8 | Frame: SA6 |

| KVA: 5 | Serial Number: 33736-11 |

| CPS: 50 | Connection Diagram: F31683/34 |

| Phase: 1 | Temperature Rise: 55C |

| RPM: 1500 | |

Brush Alternator Data Plate |

|

Rosi has to know everything! |

|

Brush Alternator Circuit Diagram |

Brush Alternator |

|

Brush Alternator |

|

Brush Alternator |

Brush Alternator |

|

Brush Alternator Control Circuit |

|

Brush Alternator Main Regulator & Aux. Preset Resistor with Circuit Diagram |

|

|

Brush Alternator Main Regulator |

|

| Interesting Lister Engine Links |

| Peter & Rita Forbes Engine Web Pages |

| The Energy Shed |

| Steve's Old Engine Shed |

| Slow Speed Engine |

| The Listeroid Page |

| History of the Lister Cold Starting Diesels |

| 1952 Lister CS 6/1 Startomatic Generator |

| Turbo Charging The Dancause 6/1 by Utter Power |

| Lister Engine Forum |

| Googles Stationary Engines Forum |

| Yahoo Group - Putting Lister CS Engines back to Work |

| Yahoo Group - Stationary Flywheel Engines |

|

Spare Parts Suppliers |

| http://volvoxengineering.com/Products.htm |

| http://www.meadplant.com/home.htm |

Visitors to this page since 18 May 2006

Back to Your Articles

Index Page

Army Radio Sales Co. Home Page