| I soaked them in water which loosened up the bottom paper

cover and removed it. Then I carefully sliced down the seam in the outer wrapper and

removed it. I then cut off the top of the zinc casing with the negative terminal still

intact. A segment of 2 inch PVC pipe was cut to approximately 6 inches. Wooden plugs were

then cut to fit the inside of the pipe. In one of these plugs a hole was drilled and a

brass screw inserted and held in place with a small block of wood. This would serve as the

Positive terminal as the screw on the carbon rod is not long enough. This plug was painted

black as in some cases the paper top cover gets destroyed in the dismantling process. The

wooden plugs were then glued in place. I used a product called RC 56 which is designed to

glue anything to anything. It works well when gluing plastic parts to wooden parts.

Several

layers of newspaper were then cut and wrapped around the PVC pipe to bring it up to the

diameter of the zinc casing and were glued in place with Elmers white Glue. Once this was

glued in place, the outer cover was glued on and the bottom cover was glued in place,

again with Elmers white glue. The screw on terminals were then put back on and we have a

corrosion proof replacement, which makes an excellent display item. There is room inside

the PVC pipe for the installation of some D Cells for those who want the battery to

provide power.

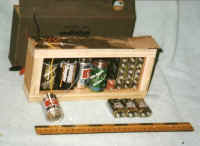

The next batteries that I tackled were the BA 48, the BA 279/U and the BA 270/U. The BA

48 provided power for the receiver portion of the SCR 694 and also provided power for the

WW II O.S.S. receiver and transmitter, the SSTR 5. The latter two batteries power the

AN/PRC 6 and AN/PRC 10 radios. These provide 1.5 volts for tube filaments and B + voltages

ranging from 67 1/2, to 90 and to 135 volts. If left alone for several years corrosion

results and they too begin to leak and destroy the outer case. These batteries are made up

of four D type cells and numerous smaller cells for the B + voltages. Once again, it is

the A cells which are zinc-carbon batteries which corrode.

I opened up the outer cardboard case and removed the batteries from the case. There is

usually some black gummy stuff which oozes and makes removal difficult. I had to open all

the seams and pry the outer cover off. Then I glued the outer cover back together part

way.

I then made a wooden frame which would fill up the inside of the the case. There were

several styles of top sections but having rebuilt three of them, I found two that were

straight forward and only needed a rectangular frame. The third required a spacer on top.

The original socket is mounted to a fibre board strip and there are four leads to the

battery packs. These should be cut off with the leads as long as possible. A hole was then

drilled in the top to allow the socket a place to rest. Smaller holes were drilled for the

connecting wires. The leads from the original socket were then fed through the smaller

holes. The fibre board strip was then fastened to the wooden frame. Staples or glue can be

used. Then the entire frame was then re inserted in the case and the case glued back

together. This is adequate for a display item to sit on the shelf.

For those who must have a working battery, there is plenty of room inside for whatever

you choose to put in there. I found that it will hold three Radio Shack D cell holders

costing 99 cents each. I wove the lead in wires through the holes in the holders which

serves to hold them together. These leads were then joined and soldered to the lead in

wires from the socket connection. Joints were covered with heat shrink tubing. A small

wooden strip was then glued in to hold them in place and keep them from shifting around

inside. This serves as the filament supply. While it will not last as long as the original

battery pack, it will provide a reasonable amount of usage.

The B supply for the BA 48 was made up from ten 9 volt transistor batteries. The BA

279/U requires fifteen of the 9 volt cells. The battery snaps were bought from Radio Shack

in packs of 5 each. They were soldered together and then soldered to the socket lead in

wires.

I left the leads at their full length for ease in handling. I would recommend that they

be made shorter when you try this. The ten 9 volt batteries are held in a pack by several

wraps of electrical tape. The connection of the clip leads were covered with heat shrink

tubing. This pack is placed at the other end of the framework and held in place by small

strips of wood, keeping in mind that you will have to replace them. Since the B batteries

will last longer than the A cells, rechargeable nicads can be used for the A battery pack

and can be recharged with out opening the case.

The entire assembly is then slid back into the outer card stock casing. In this case,

you will want to be able to gain access to them so the bottom cover was held in place by

two straps of sticky Velcro obtainable from most craft stores.

A more sophisticated system can be made using an inverter power supply developed by

Dennis Starks for this purpose. In this case, the frame is made about 1/4 inch too thin

and a wooden side panel is glued in place. this serves as a place to mount the circuit

boards and keep then from bumping into each other and shorting out, etc. This system was

designed to operate from re-chargeable gel cells. While it is a bit more difficult to

construct, in the long run it will save on the cost of replacing the 9 Volt transistor

batteries.

The BA 270/U presents the most difficult challenge as the unit is not a square but has

sloping sides. It also requires a C voltage of 4.5 volts. A wooden bottom was made , a top

panel with the sides cut to the slope of the original battery and two end panels were cut

and glued together. A hole was cut in the end panel for the power socket. The interior of

this battery pack has much less space than the others. In this one the space allows for

the B battery pack but the A supply was C cells. C Cell holders are available from Radio

Shack. |